Why Single Use Surgical Twist Drill bits?

Improve your chances of a positive outcome with single-use surgical drill bits vs reprocessed twist drills.

- Eliminate Patient Cross Contamination

- ISO Certified Sterility

- Better Heat Management

- Shorter Plunging Depth

Learning about the risks associated with reusing and reprocessing surgical cutting accessories can help clinicians understand the benefits single-use drill bits can provide to patient care and recovery.

Eliminate Patient to Patient Cross Contamination

One of the greatest risks with reprocessing drill bits in consecutive surgeries is cross contamination which can lead to infection. A 2002 resterilization study 1 found up to 40% of single-use devices remained unsterile after resterilization, even when attempting to clean according to regulatory standards for sterility. It was concluded that “None of the reprocessed Single use devices were effectively cleaned or sterilized”. 1 The risk of infection due to cross contamination is always greater when reusing a surgical drill bit. Cross contamination risk is reduced when using a new single-use device because it has never contacted another patient. A single accidental oversight in cleaning can lead to a negative outcome.

ISO Certified Sterility

- Single-use devices are sterilized by the manufacturer per ISO global quality standards to ensure maximum protection for the patient and hospital staff.

- Single-use drill bits contain no bioburden from previous surgeries, whereas used drill bits have no guarantee of cleanliness or sterility. 1

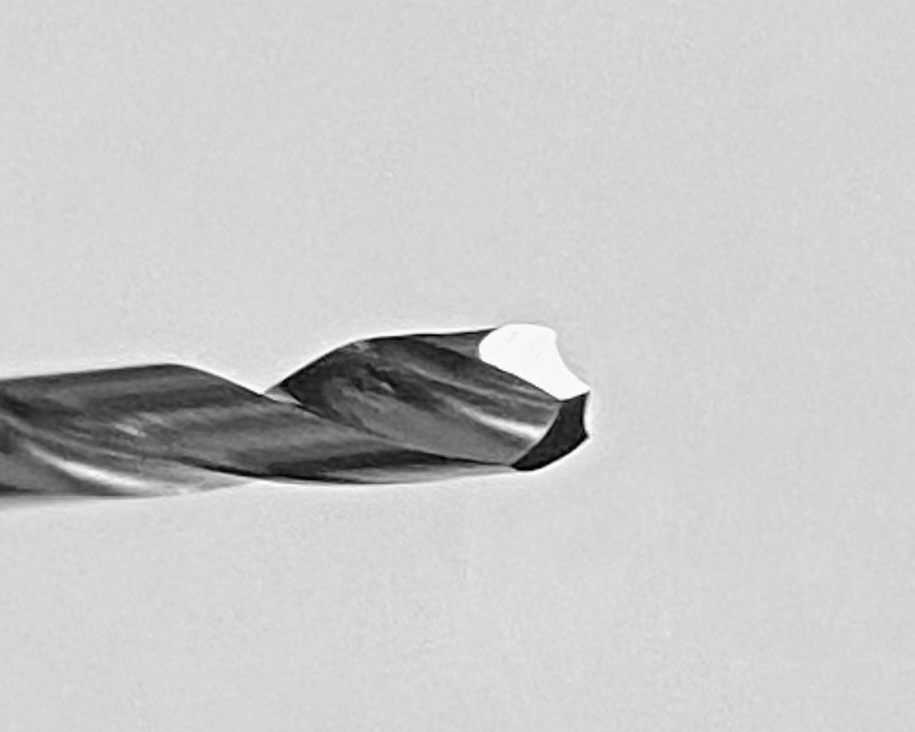

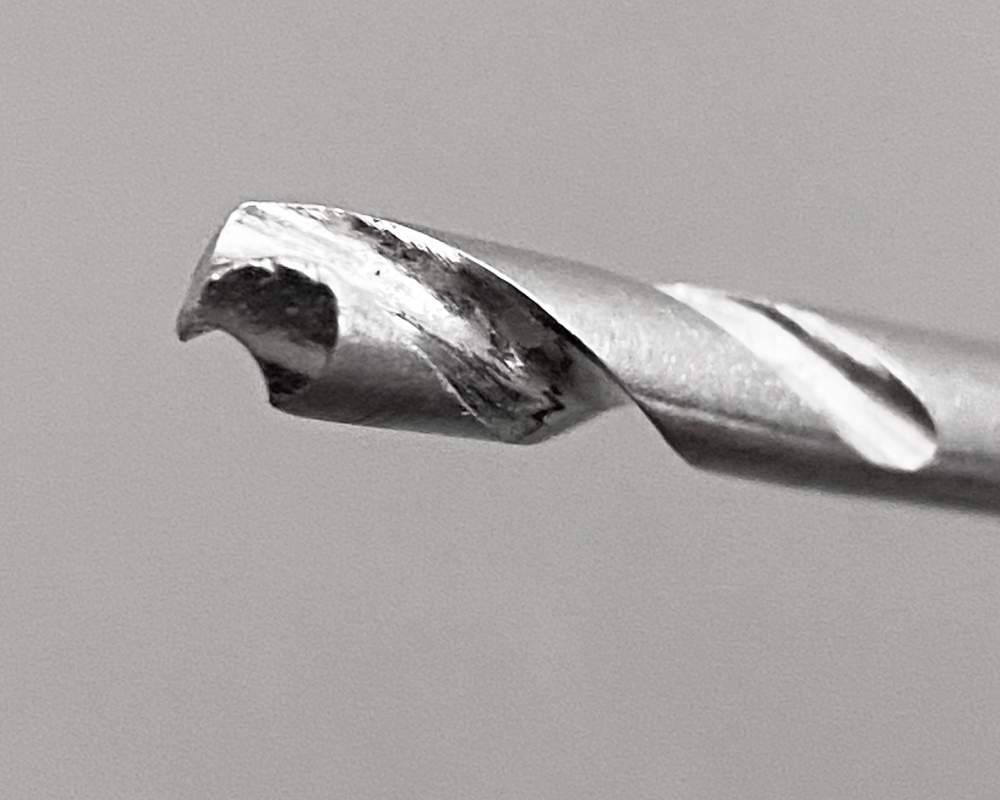

Heat Management Comparison Between Single Use And Reused Drill Bits

Sharp surgical drill bits cut smoothly and efficiently. A sharp edge removes more material with each revolution and limits friction. As a drill point dulls with reuse, less material is removed with each cut resulting in increased cutting time and heat buildup from friction. The recorded difference between a new and reprocessed drill bit is substantial, and there is up to a 350% increase in heat generation when reusing drill bits. 2 The resulting heat buildup increases the risk of thermal osteonecrosis.

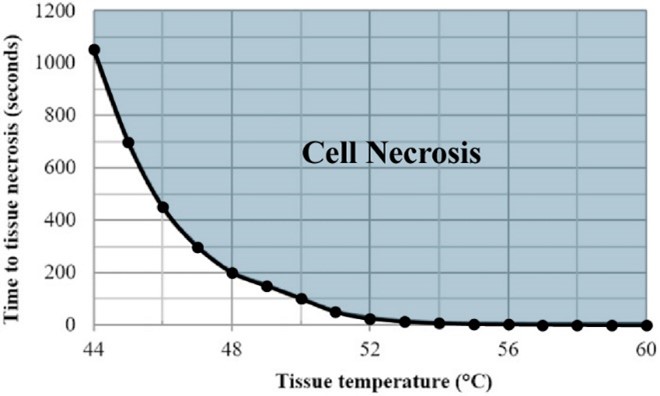

Thermal Necrosis

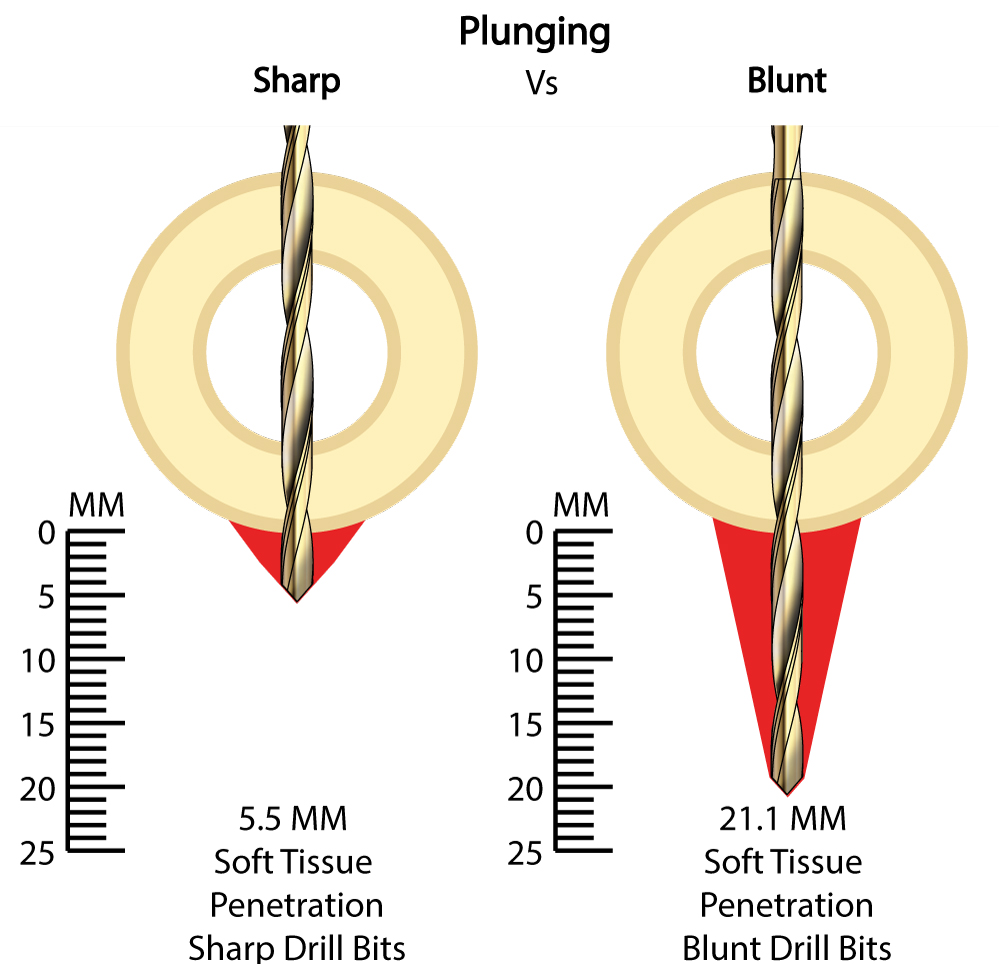

Shorter plunging depth aiding Soft Tissue Protection and accuracy

In a plunging study conducted in 2012 5, researchers tested sharp vs dull drill bits. Twenty experienced Surgeons plunged 3 holes into normal and osteoporotic bone. The results measured an average of 5.1 – 5.4 MM penetration depth respectively when using a sharp drill bit. Repeating the same test with blunted twist drills, surgeons averaged 21.1 – 22 MM plunging depth. Even for experienced surgeons, the plunging depth averaged 4 times greater when using a dull surgical twist drill bit because of the extra pressure required to engage the drill tip. The additional penetration depth increases risk of soft tissue, vascular, and nerve trauma. 5

The Best Choice

Every patient deserves the best care possible. When considering the benefits of single use surgical twist drill bits compared to reprocessed drill bits, the only potential benefit of reprocessed drill bits is the initial cost savings; however, any cost benefit can quickly disappear with even a single negative clinical outcome. The potential complications, procedural failures, and risk far outweigh any monetary benefit. Patients can be directly affected by the hospital’s decision to reprocess drill bits. Given the evidence, to maximize the clinical outcome single use sterile packaged drill bits are the clear choice for every surgery.

Resources

References

- Roth K, Heeg P, Reichl R. Specific hygiene issues relating to reprocessing and reuse of single-use devices for laparoscopic surgery. Surg Endosc. 2002 Jul;16(7):1091-7. doi: 10.1007/s00464-001-9190-7. Epub 2002 Apr 9. PMID: 12165829.

- W. Allan, E.D. Williams, C.J. Kerawala, Effects of repeated drill use on temperature of bone during preparation for osteosynthesis self-tapping screws, British Journal of Oral and Maxillofacial Surgery, Volume 43, Issue 4, 2005, Pages 314-319, ISSN 0266-4356, https://doi.org/10.1016/j.bjoms.2004.11.007.

- Timon, Charles, and Conor Keady. “Thermal Osteonecrosis Caused by Bone Drilling in Orthopedic Surgery: A Literature Review.” Cureus, Cureus, 24 July 2019, http://www.ncbi.nlm.nih.gov/pmc/articles/PMC6759003/

- Zhang, Jinao & Hills, Jeremy & Zhong, Yongmin & Shirinzadeh, Bijan & Smith, Julian & Gu, Chengfan. (2019). Modeling of soft tissue thermal damage based on GPU acceleration. Computer Aided Surgery. 24. 5-12. 10.1080/24699322.2018.1557891.

- Alajmo, Giuseppe & Schlegel, Urs & Gueorguiev, Boyko & Matthys, Romano & Gautier, Emanuel. (2012). Plunging When Drilling: Effect of Using Blunt Drill Bits. Journal of orthopaedic trauma. 26. 482-7. 10.1097/BOT.0b013e3182336ec3.